Ever wondered how engineers and researchers can test the strength and durability of concrete before it’s even mixed? Enter VCCTL (Virtual Cement and Concrete Testing Laboratory), a powerful tool that allows you to model and analyze the mechanical properties of concrete before it’s even mixed. Let’s dive into how you can leverage VCCTL to develop smarter concrete models and gain deeper insights into its behavior.

Step-by-Step Tutorial on Using VCCTL

1. Getting Started: Installing VCCTL

Before diving into simulations, download and install the VCCTL software from the NIST website. VCCTL is compatible with most modern systems, but ensure your system meets the technical requirements to handle simulation data.

Once installed, launch the program, and familiarize yourself with the user interface. You’ll find a variety of modules to simulate different aspects of concrete and cement.

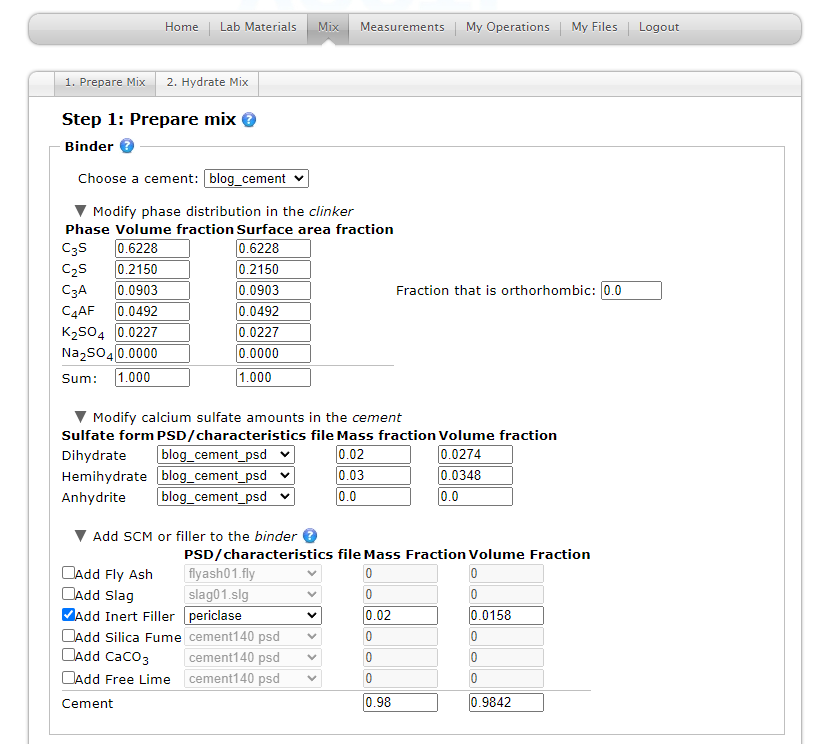

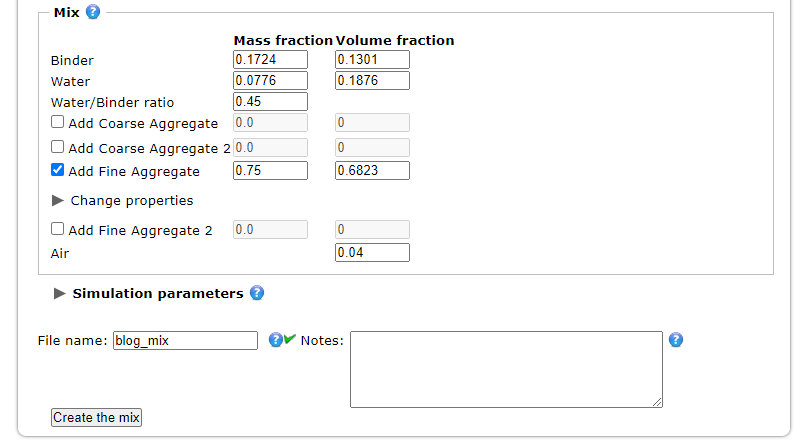

2. Prepare the mix

The first step is to specify the cement you will use. You can select a default option or define the composition yourself by specifying the fraction of each phase (e.g., C3S, C2S), whether sulfates or supplementary cementitious materials will be added, and more. Additionally, you can include fine and coarse aggregates and define the water/binder ratio.

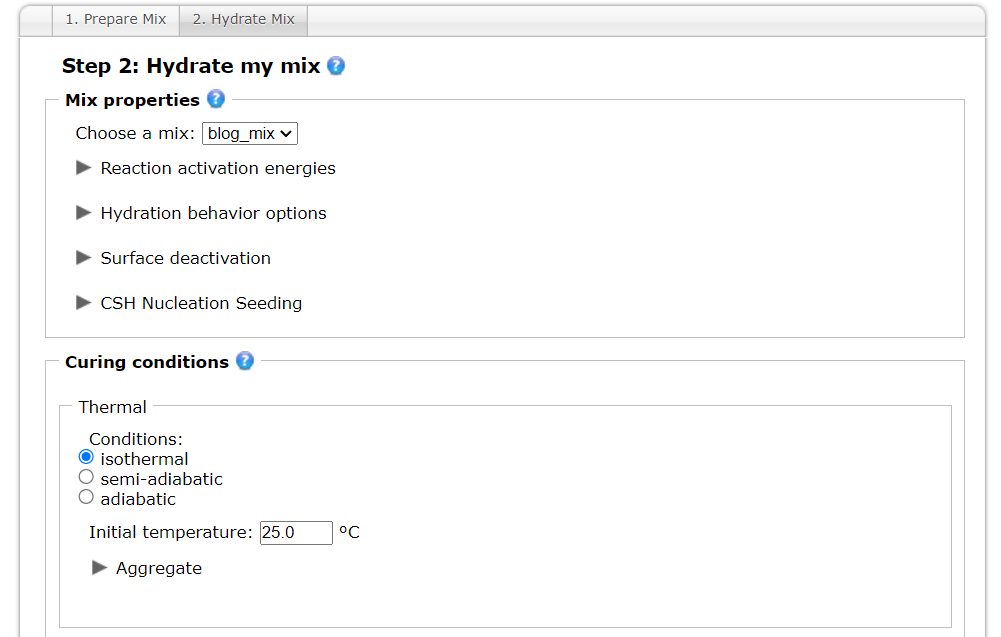

3. Simulating Hydration

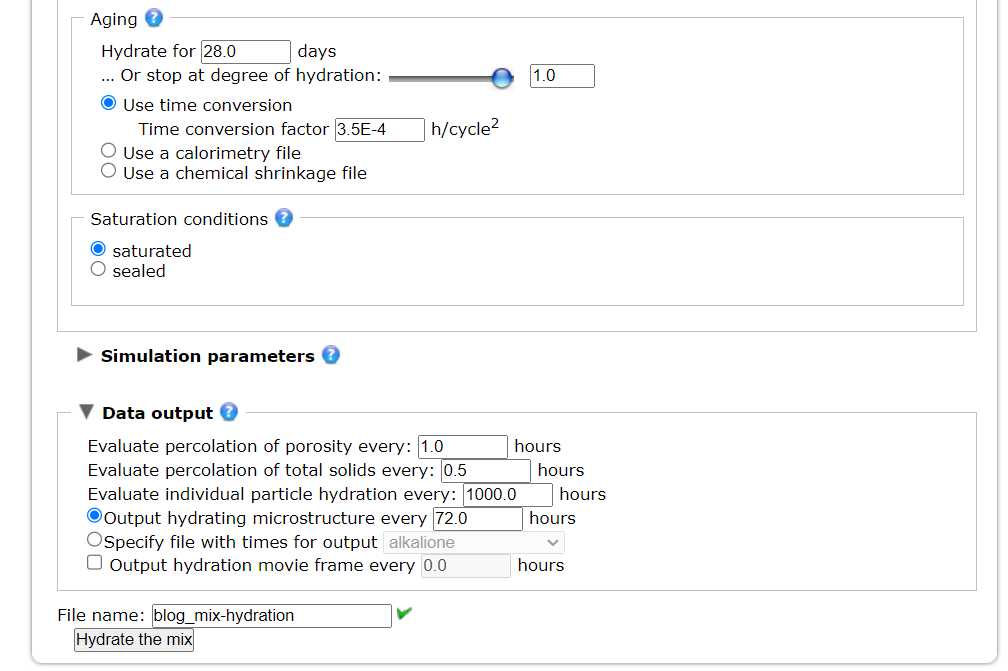

The next step is to simulate the cement hydration process, a key step in determining the final properties of the concrete.

Important parameters to define during hydration include curing conditions, such as thermal settings (isothermal, semi-adiabatic, or adiabatic), aging, and saturation conditions. Specify your desired output and save the hydration process with a unique name for easy reference.

4. Running Simulation

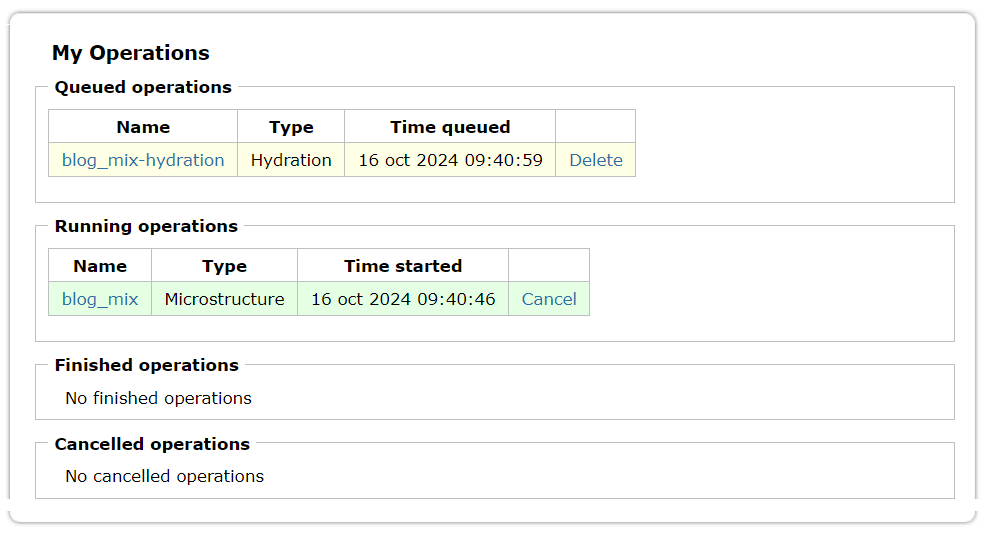

VCCTL operates using a queue system. It shows which operations have finished, which are currently running, and those still in the queue. These queued operations will automatically run in order, ensuring a smooth workflow.

5. Hydration Results

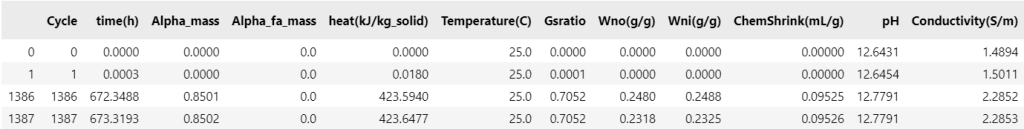

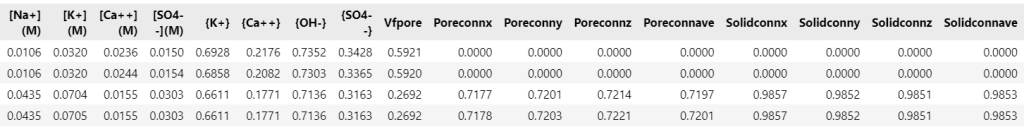

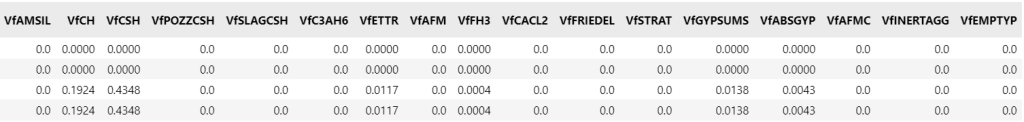

Once hydration is fully computed, results can be analyzed through the Measurements window or exporting the data from the «My Files» section. The hydration results file contains critical information such as the degree of hydration, conductivity, and the volume fraction of each phase over time, among other outputs.

Additionally, VCCTL allows you to visualize the microstructure at any point during the hydration process.

6. Mechanical and Transport Properties

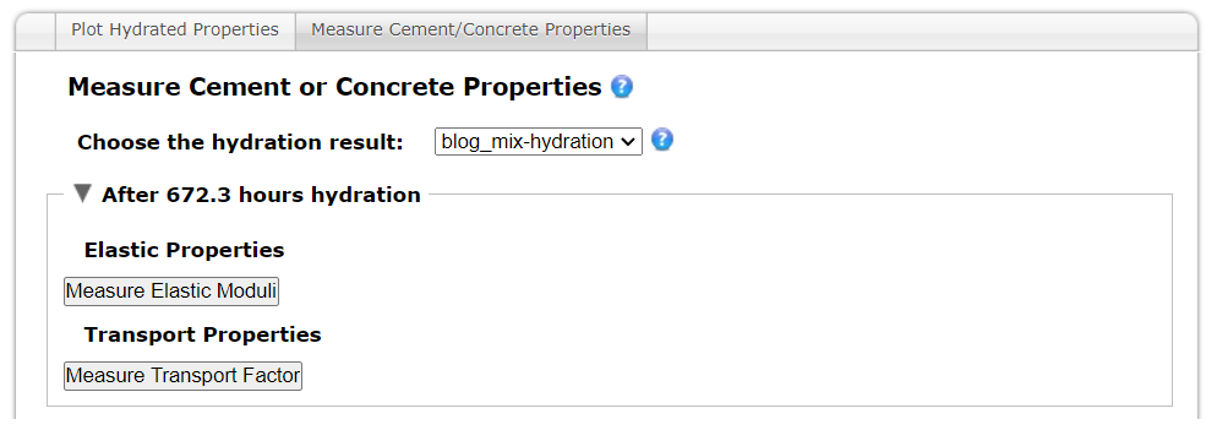

One of VCCTL’s most valuable features is its ability to predict the mechanical properties of concrete. Once hydration is complete, you can simulate properties such as the Elastic Modulus and Compressive Strength.

To calculate these properties, navigate to the Measurements window, select the desired time step, and click “Measure Elastic Moduli” or “Measure Transport Factor.” These simulations are based on the generated microstructure and provide insights into how the concrete will perform under stress.

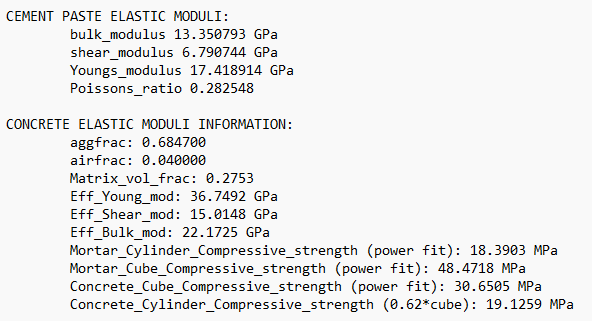

7. Mechanical properties / Transport results

The output of the mechanical properties simulation provides not only the elastic modulus but also the shear modulus, bulk modulus, and Poisson’s ratio. If aggregates have been added, the output will also include these properties for the mortar or concrete as well as the compressive strength.

Conclusion

VCCTL is a powerful tool that helps engineers and researchers design better concrete by simulating its properties before it’s mixed. It lets you see how the concrete will behave during hydration and predict important characteristics like strength and durability. With VCCTL, you can adjust your mix for optimal performance, saving time and resources by cutting down on physical testing. Whether you’re aiming to improve strength, durability, or tailor your mix for a specific project, VCCTL makes the process easier and more efficient.